|

| December 07, 2021 | Volume 17 Issue 45 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

SPE names winners of annual Automotive Innovation Awards

The Automotive Division of the Society of Plastics Engineers (SPE) recently announced the winners of its 50th annual Automotive Innovation Awards, the oldest and largest competition of its kind in the world serving the automotive and plastics industries. The announcement was made Nov. 10, 2021, during an awards gala held at the Burton Manor in Livonia, MI.

The Chassis/Hardware category winner was also this year's Grand Award winner. The Grand Award winner was selected from the winners of each of seven categories by a panel of judges who are industry experts. A Vehicle Engineering Team Award (VETA) was also announced. The VETA honors work in research, design, engineering, and/or manufacturing that has led to the significant integration of polymeric materials on a notable vehicle.

This year, a special category was added to recognize Innovative Automotive Industry Plastic Solutions for COVID-19 Protection. This honors the outstanding effort of the automotive industry to provide much needed Personal Protective Equipment (PPE) during the early days of COVID-19, bringing capacity to the market with automotive design and production strength at the same time most companies were dealing with COVID-19 shutdowns.

The winners of the 50th annual Automotive Innovation Awards are:

GRAND AWARD & CATEGORY WINNER: Chassis/Hardware

Multi-Material Rear Leaf Spring

- OEM Make & Model: 2021 Ford Motor Co. Ford F150

- Tier Supplier/Processor: Rassini Suspensiones/Rassini Suspensiones, SGL Carbon

- Material Supplier/Toolmaker: Hexion Inc., SGL Carbon/Not Available

- Material /Process: EPIKOTE Resin TRAC 06150, EPIKURE Curing Agent TRAC 06150, HELOXY Additive TRAC 06805/ High Pressure Transfer Molding (HP-RTM)

- This new hybrid rear leaf spring combines a high-strength steel main pack plus an HP-RTM fiberglass-reinforced epoxy composite helper that reduces mass 30% while providing the same stiffness and durability as a conventional steel leaf spring system. Additional benefits include increased payload capability, lower part count, decreased interleaf friction, smoother engagement, lower noise, and lower carbon footprint.

CATEGORY WINNER: Additive Manufacturing

Integrated Tether System

- OEM Make & Model: 2021 Ford Motor Co. Ford Maverick

- Tier Supplier/Processor: IAC Group/IAC Group

- In an industry first, customers can select, download NFTL files, and 3D print their own swappable accessories (e.g., cupholders, trash bins, etc.) that fit in storage slots of their vehicle across the entire Maverick series. Initial designs were developed by Ford and its supply teams, but future ones could be suggested by customers. A variety of printer types and suggested materials can be used. This provides customers with flexible, customizable storage and use features or the option to maximize cabin space while avoiding significant tooling investment.

CATEGORY WINNER: Body Exterior

Grille with Integrated Lit Emblem

- OEM Make & Model: 2021 Ford Motor Co. Ford Mustang Mach E GT

- Tier Supplier/Processor: Magna Exteriors/LexaMar Div. of Magna Exteriors

- Material Supplier/Toolmaker: Covestro/Inevo Group

- Material/Process: PC/Injection Compression Molding

- This hardcoated and painted front grille with lit emblem provides a 3D, futuristic effect in a single part. Injection/compression molding forms the large-format clear PC grille with variable wall thicknesses (ranging from 3-5 mm) in a lower-tonnage press that helped minimize or eliminate flow lines and stress marks. After molding, the optical-quality part undergoes hardcoat silicone dip to provide excellent weathering and abrasion resistance, the pony emblem is milled out, and primer and paint are selectively applied to the B side of the part -- the first use of paint-over-hardcoat for an auto exterior trim application.

CATEGORY WINNER: Body Interior

3rd Row Seatback

- OEM Make & Model: 2021 Toyota Motor Corp. Toyota Sienna

- Tier Supplier/Processor: Toyota Boshoku Corp./Flex-N-Gate Corp.

- Material Supplier/Toolmaker: BASF Corp./Concours Technologies, Inc.

- Material/Process: Ultramid B3ZG7 CR PA 6/Injection Molding

- A 16-piece steel assembly was replaced with a single, shoot-and-ship plastic assembly for this 3rd-row seatback that reduced mass 30%, costs 15%, represented a 2x improvement in crash performance, and takes 63% less effort for occupants to raise the seat to its upright position, eliminating the need for a seat motor. This is the industry's first fully plastic freestanding seatback offering excellent energy absorption without the need for metal support brackets. A new 35% short-glass, impact-modified PA6 resin was developed for this sequentially injected application.

CATEGORY WINNER: Environmental

Wiring Harness Clip

- OEM Make & Model: 2021 Ford Motor Co. Ford Bronco Sport

- Tier Supplier/Processor: Lear/HellermannTyton North America

- Material Supplier/Toolmaker: DSM/HellermannTyton North America

- Material/Process: Akulon RePurposed PA6 PA6/Melt Compounding, Injection Molding

- These rPA6 wire-harness clips are injection molded from 100% PCR ocean plastics. Ghost gear (fishing nets) is collected by fishermen in the Indian Ocean and Arabian Sea, providing jobs, more sustainable livelihoods, and healthier marine life. The material provides comparable performance to petroleum-based prime resin at 10% cost savings, lower energy, improved supply-chain stability, and LCA benefits. No tooling changes and minimal process changes were needed for this drop-in change.

CATEGORY WINNER: Materials

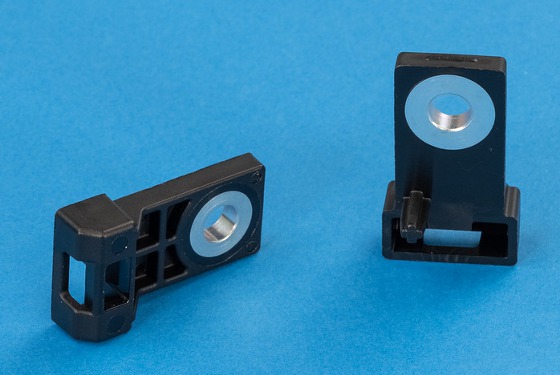

Composite Roof Receivers

- OEM Make & Model: 2021 Stellantis Jeep Wrangler and Jeep Gladiator

- Tier Supplier/Processor: Stellantis/Not Available

- Material Supplier/Toolmaker: Mitsubishi Chemical Advanced Materials/Maple Mold Technology

- Material/Process: KyronMAX S-4330 PPA w/ 30% USCF/Injection Molding

- Six brackets for removable hard-top and soft-top roofs were converted from investment cast steel to 30% ultrashort carbon fiber (USCF)-reinforced PPA, providing comparable part strength while reducing costs 38% and mass 79%. Powder coating was eliminated and scratch and mar improved while providing a weatherable, MIC, Class A finish that allowed for mid-program replacement and backwards service compatibility. The USCF composite molds like neat polymers but outperforms LFT materials, is fully recyclable, and has a lower carbon footprint than metal/alloy parts. Direct-drop valve gates and T-nut fasteners also were key enablers.

CATEGORY WINNER: Process/Assembly/Enabling Technologies

Thick Lightbar Development

- OEM Make & Model: 2021 General Motors Co. Cadillac Escalade

- Tier Supplier/Processor: Valeo Lighting Systems/Valeo Lighting Systems

- Material Supplier/Toolmaker: Covestro LLC/Windsor Mold Group

- Material/Process: Makrolon LED PC/Multi-cavity, Multi-shot Injection Molding

- This challenging 780-mm-long and 18-mm-thick transparent-red light blade for rear taillamps functions offers a unique appearance and homogeneous lit appearance. Keys to making the patented application work were advanced simulation tools for design and functional optimization and warpage control; complex runner, parting line, shutoff valves, and multi-shot injection process control; plus a custom-formulated optical-grade PC that helped manage quality, cost, and molding capacity and met all legal rear-lighting requirements. Despite technical challenges, program timing was reduced by 3 months and $250,000 in prototype tooling was avoided through virtual prototyping.

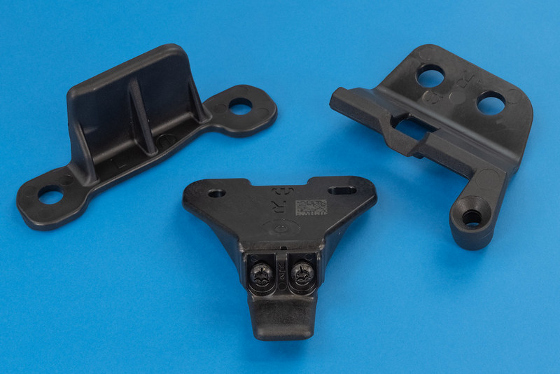

CATEGORY WINNER: Industry Solutions for COVID-19

Powered Air Purifying Respirator

- OEM Make & Model: 2020 Ford Motor Co. Limited Use PAPR

- Tier Supplier/Processor: Ford Motor Co./Denso Corp.

- Material Supplier/Toolmaker: Asahi Kasei America, Inc., Celanese/3Dimensional Services, Protolabs

- Material/Process: PPTD40, POM Asahi P-40TC-1102 NT101, Celanese M90 CF2001 PolyPro, POM/Injection Molding

- The team produced the first all-plastic PAPR, converting previously metal components to plastic to reduce mass and costs and improve user comfort for this personal protective equipment used by medical workers caring for COVID patients. The lighter, more efficient design improved battery life, enabling workers to complete a 12-hr shift without needing to recharge the battery. NIOSH certification was achieved in just 3 days on the first try. Production was increased to 8,500 units/week from the 650/week the previous supplier achieved. All profits from sales were donated to COVID-19 relief funds and four patents are pending on the unit.

---------------------------

CATEGORY WINNER: Vehicle Engineering Team Award (VETA) - Ford Motor Co. 2021 Ford F-150

The team at Ford Motor Co. (Dearborn, MI) and its suppliers that developed the 2021 model year Ford F-150 pickup have been named the Vehicle Engineering Team Award (VETA) winner. The VETA award was created by SPE in 2004 to recognize the technical achievements of entire teams -- comprised of automotive designers, and engineers, tier integrators, materials suppliers, toolmakers, and others -- whose work in research, design, engineering, and/or manufacturing has led to significant integration of polymeric materials on notable vehicles. For 44 years, F-Series has been the bestselling pickup in the U.S., and the 2021 edition features numerous plastics and composites innovations, many of which were nominated in other categories of this year's competition, including:

Body Exterior Nomination:

- Cowl Vent Grille

- Armrest Insert

- Max Recline Seat

- 1st-Row Center Seat Mobile Workstation

- Upper Glovebox with Remote Release

- Work Surface Foldout Armrest

- Multimaterial Rear Leaf Spring

- Folding Shifter

- Coolant Flow Management Baffle

---------------------------

To commemorate "50 Years of Plastics Innovation," instead of picking a single Hall of Fame (HOF) Winner for 2021, the HOF committee selected the Top 5 leading innovations from the previous 37 winners -- from 1983 to 2019. The criteria for a HOF award is that the nomination be in use for at least 15 years and be: game changing; very successful worldwide; innovative in materials, process and application; and still being used. A Lifetime Achievement award was also presented.

CATEGORY WINNERS -- Top 5 Hall of Fame Awards from 1983-2019:

- HDPE (High-Density Polyethelene) Fuel Tank awarded to Volkswagon AG in 2000

- Front & Rear TPO (Thermoplastic Polyolefin) Bumper Fascias awarded to General Motors Co. in 2010

- PVB (Polyvinyl Butyral) Windshield Interlayer awarded to Ford Motor Co. in 1988

- PA (Nylon) Thermoplastic Intake Manifold awarded to Porsche AG in 2005

- PC (Polycarbonate) Headlamp Assembly awarded to Ford Motor Co. in 2007

---------------------------

To see all the finalists and learn more about the awards and event, go to https://speautomotive.com/innovation-awards-competition-and-gala/.

Source: Society of Plastics Engineers

Published December 2021

Rate this article

View our terms of use and privacy policy